Over 2.5 million dollars in inventory!

Profile

Search

Shopping cart

You have no items in your shopping cart.

Flow Control Valves

Flow control functions for applications up to 350 bar (5000 psi) and 350 L/min (92 USgpm)

Danfoss flow control valves precisely factor in the temperature, pressure and volume of flow for efficient handling of each application. Whether the hydraulic system requires integrated relief screw-in cartridge valves, pressure compensation or a more specific combination of features, we can provide the perfect fit.

Features:

- Products in this catalog have been Fatigue tested to one million cycles at 132% or 10 million cycles at 115% of rated pressure.

- Non-adjustable, pressure compensated, flow regulator for flows to 227 L/min (60 USgpm).

- Adjustable, pressure compensated, flow regulator for flows to 114 L/min (30 USgpm).

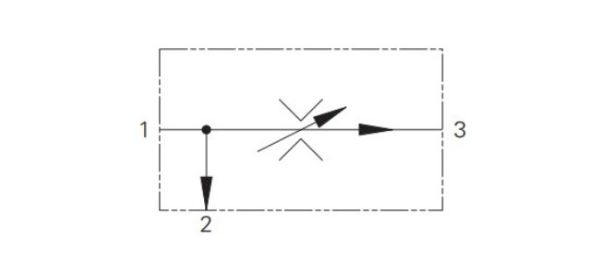

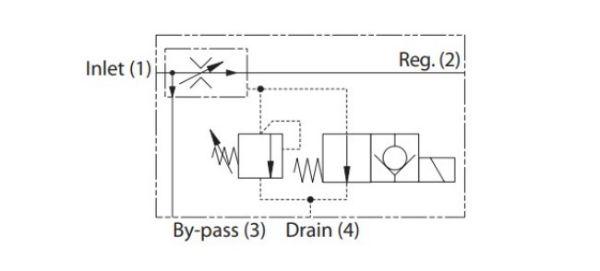

- Fixed and adjustable priority bypass type flow regulator for regulated flows to 114 L/min (30 USgpm).

- Adjustable flow control without free reverse flow check with flows rated to 114 L/min (30 USgpm).

- Adjustable flow control with free reverse flow check with flows rated to 45 L/min (12 USgpm).

- Needle valves with flows rated to 265 L/min (70 USgpm).

- Velocity fuses with flows rated to 227 L/min (60 USgpm).

- Flow divider/combiners (FDC1 and FDC11) with flows rated to 568 L/min (150 USgpm).

- Posi-traction valves (FDC13) with flows rated to 567 L/min (150 USgpm)

- Operating pressures to 350 bar (5000 psi).

Benefits:

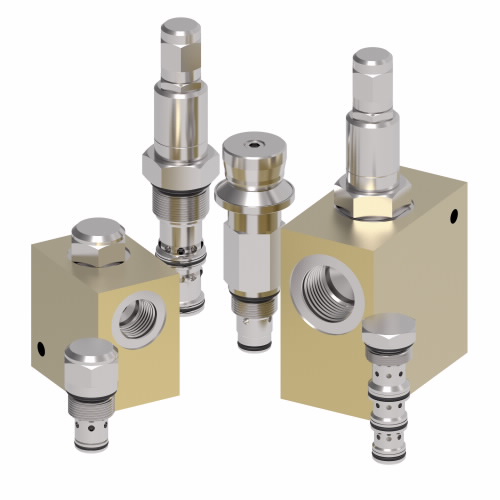

- All operating parts are hardened steel, ground and honed for long life and low leakage.

- Designed for maximum flexibility and minimal space requirements.

- All exposed cartridge surfaces are zinc dichromate plated to resist corrosion. Steel housings are available for cartridges rated to 350 bar (5000 psi) application pressures.

- All aluminum manifolds are gold anodized to resist corrosion.

- Reliable, economical and compact.

- Low leakage.

- Variety of adjustment options.

- Adjustments designed not to go spring solid at “full in” position or to allow the adjustment to be removed when backed out.

- FR1-16 Flow Regulator - Fixed, pressure compensated

- FR5-10 Flow Regulator - Fixed, pressure compensated

- FR5-8 Flow Regulator - Fixed, pressure compensated

- FR1-20 Flow Regulator - Fixed, pressure compensated

- FR2-16 Flow Regulator - Limited range, adjustable pressure compensated

- FR2-10 Flow Regulator - Limited range, adjustable pressure compensated

- FAR1-10 Flow Regulator - Fully adjustable, pressure compensated with free reverse flow

- FAR1-12 Flow Regulator - Fully adjustable, pressure compensated with free reverse flow

- FAR1-16 Flow Regulator - Fully adjustable, pressure compensated with free reverse flow

- 2CFRC60 Flow Regulator - Restrictive, pressure compensated with reverse check

- PFR5-10 Flow Regulator - Fixed, priority type, pressure compensated

- PFR11-12 Flow Regulator - Fixed, priority type, pressure compensated

- PFR15-10 Flow Regulator - Fixed, priority type, pressure compensated

- PFR5-8 Flow Regulator - Fixed, priority type, pressure compensated

- PFR11-16 Flow Regulator - Fixed, priority type, pressure compensated

- 2CFP60 Flow Regulator - Adjustable, priority type pressure compensated

- PFR2-16 Flow Regulator - Limited range adjustable, priority pressure compensated

- PFR12-10 Flow Regulator - Adjustable, priority type pressure compensated

- PFR2-10 Flow Regulator - Priority flow regulator, adjustable

- PFR12-12 Flow Regulator - Adjustable, priority type pressure compensated

- PFR12-16 Flow Regulator - Adjustable, priority type, pressure compensated

- PFRD/S-12 Priority Flow Control - Spool type, load sensing

- PFRD/S-16 Priority Flow Control - Spool type, load sensing

- PFRD/S-20 Priority Flow Control - Spool type, load sensing

- MRV2-10 Flow Restrictor Valve - Semi-rotary

- MRV2-16 Flow Restrictor Valve - Semi-rotary

- 2CR80 Flow Restrictor Valve - Needle with free reverse flow check

- FCV6-16 Flow Restrictor Valve - Needle valve

- NV1-10 Flow Restrictor Valve - Needle valve

- FCV7-10 Flow Restrictor Valve - Needle valve

- NV1-8 Flow Restrictor Valve - Needle valve

- FCV11-12 Flow Restrictor Valve - Needle valve

- NV1-16 Flow Restrictor Valve - Needle valve

- NV1-20 Flow Restrictor Valve - Needle valve

- PCS3-10 Pressure compensator - Restrictive

- PCS13-10 Pressure compensator - Restrictive

- PCS13-12 Pressure compensator - Restrictive

- PCS3-16 Pressure compensator - Restrictive

- PCS3-20 Pressure compensator - Restrictive

- PCS3-12 Pressure compensator - Restrictive

- PCS13-16 Pressure compensator - Restrictive

- PCS4-10 Pressure compensator - Bypass or priority

- PCS14-10 Pressure compensator - Bypass or priority

- PCS14-12 Pressure compensator - Bypass or priority

- PCS4-16 Pressure compensator - Bypass or priority

- PCS14-16 Pressure compensator - Bypass or priority

- PCS4-20 Pressure compensator - Bypass or priority

- PCS4-12 Pressure compensator - Bypass or priority

- 2FPH195 Flow Regulator - Pressure compensated regulator/diverter, priority style. solenoid switch

- 2FPH55 Flow Regulator - Pressure compensated regulator/diverter, priority style. solenoid switch

- 2FPH95 Flow Regulator - Pressure compensated regulator/diverter, priority style. solenoid switch

- 2FPH250 Flow Regulator - Pressure compensated regulator/diverter, priority style. solenoid switch

- 2FPH350 Flow Regulator - Pressure compensated regulator/diverter, priority style. solenoid switch

- VF1-10 Velocity fuse

- VF1-16 Velocity fuse

- VF11-10 Velocity fuse

- 2CFD200 Flow Divider/Combiner - Pressure compensated, spool type

- FDC1-16 Flow Divider/Combiner - Pressure compensated, spool type

- FDC11-16 Flow Divider/Combiner - Pressure compensated, spool type

- 2CFD50 Flow Divider/Combiner - Pressure compensated, spool type

- FDC1-20 Flow Divider/Combiner - Line mounted, pressure compensated, spool type

- FDC1-10 Flow Divider/Combiner - Line mounted, pressure compensated, spool type

- FDC3-16 Flow Divider/Combiner - Pressure compensated, spool type, posi-traction

- FDC3-20 Flow Divider/Combiner - Pressure compensated, spool type, posi-traction