Over 2.5 million dollars in inventory!

Profile

Search

Shopping cart

You have no items in your shopping cart.

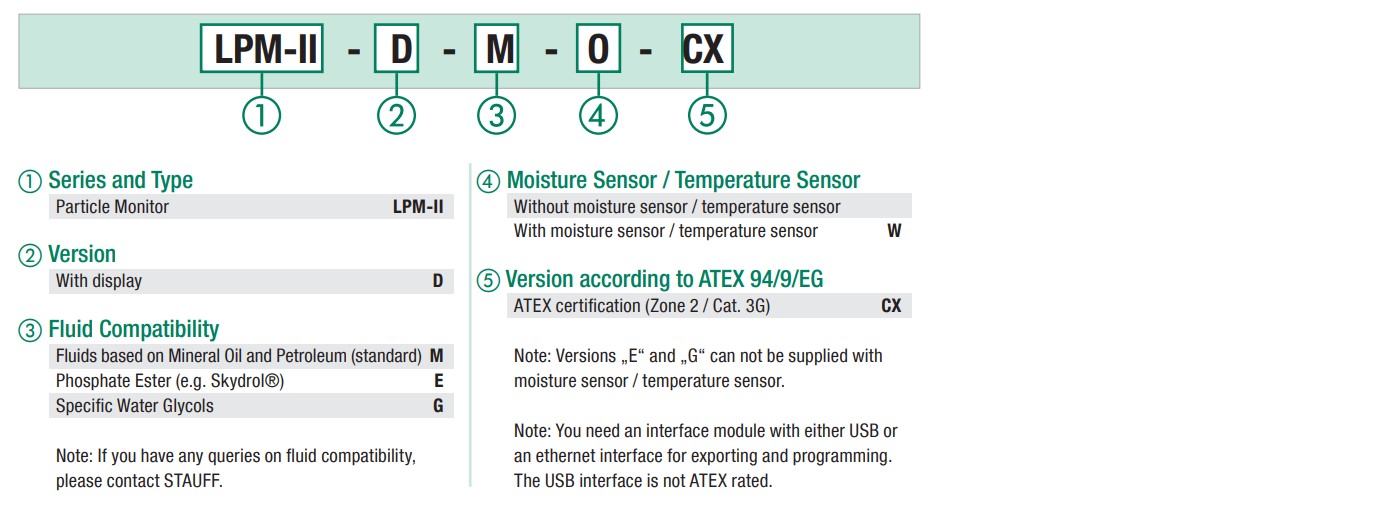

LPM-II-CX Particle Monitor (ATEX)

The ATEX version of the Particle Monitor LPM-II is approved for use in hazardous areas (zone 2/category 3G). The device thus meets the conditions to be used in e.g. oil and gas industry or chemical and process industry.

Product Features

- Determines contamination level of measured fluids in 8 size particle channels

- Precise and complete determination of particle sizes in accordance with international standards

- Integrated data storage for up to 4000 measuring results

- Integrated Modbus and CAN Bus interfaces can be used to connect the device to existing machine control, and data acquisition systems

- Option to specify different alarm thresholds

- Software on CD (included)

- ATEX compliant (Zone 2/Category 3G)

Technical Data

Channels

- >4, 6, 14, 21, 25, 38, 50, 70 µm(c) acc. to ISO 4406:1999

Measuring Range/Purity Classes

- ISO 4406:1999 Code 0 to 25, NAS 1638 classes 00 to 12,

AS4059 Rev. E. tables 1 and 2 sizes A-F: classes 000 to 12,

ISO 11218 classes 00 to 12 (lower codes or classes are test time-dependent)

Accuracy

- ±1/2 code for 4, 6, 14 µm(c)

- ±1 code for larger particles

Calibration

- Each device is individually calibrated using ISO Medium Test Dust (MTD) in accordance with ISO 11171 (1999)

Flow

- 20 to 400 ml/min (.005 to .11 US GPM)

Viscosity Range

- ≤ 1000 mm²/s

Temperature Range

- Media: -25 °C to + 80 °C (-13 °F to +176 °F)

- Ambient: -5 °C to +80 °C (+23 °F to +176 °F)

Weight

- 5,5 kg (12.16 lbs)

Power Supply

- 9 to 36 VDC

Fluid Compatibility

- M: suitable for Synthetic and Mineral Oil based fluids, Diesel and Petroleum

- G: Austenitic Stainless Steel, FKM (Viton®): suitable for offshore and aqueous fluids

- E: Austenitic Stainless Steel, Per fluorinated Rubber (FFKM): suitable for Phosphate Ester and aggressive media

Max. Permissible Operating Pressure

- 400 bar (5801 PSI) (Note: In systems with extreme pressure peaks, please contact STAUFF)

Test Duration

- Settable between 10 to 3600 sec., set ex-works to 120 sec.

- As standard with start delay and freely programmable test intervals

Moisture Sensor/Temperature Sensor

- % RH (relative humidity) ±3 %

- ±3 °C (±32 °F)

Volumetric Flow Measurement

- As display only

Hose Connections

- Test coupling STAUFF Test 20 or comparable (M16 x 2)

Data Storage

- Max. 4000 measuring results

Interfaces

- RS485, RS232, Modbus, CAN Bus

Current Consumption

- 12 V: 70 mA

- 24 V: 40 mA

- 36 V: 30 mA

Power

- <2,2 W

Housing Surface Treatment

- Polyester vinyl paint (light grey)

- Cast

- Stainless Steel

- Material spec.: ANC ABF/C

Wetted Parts

- M: C46400 Cu Alloy, 316 Stainless Steel, FKM (Viton®), FR4, Sapphire

- G: 316 Stainless Steel, FKM (Viton®), Sapphire

- E: 316 Stainless Steel, Per fluorinated Rubber (FFKM), Sapphire, EPDM

LPM-II-CX Particle Monitor (ATEX)

Sort by

Display items per page

Recently viewed

CMA2004JMSV3M00006706806906910

CMA2004JMSV3M00006706806906910  GH781-10

GH781-10  BCC A315-A315-30-330-VS85N6-006

BCC A315-A315-30-330-VS85N6-006