Pressure Unloading/Relief Functions

In addition to providing the basic relief function the unloading relief function provides the means of automatically loading/unloading a fixed delivery pump according to system demands. The high pressure side of the hydraulic system is connected, via port X, to a small piston fitted in front of the poppet of the pilot relief stage in the unloader cover. When system pressure on port A reaches the pressure setting of the pilot stage, the valve, acting as a relief valve, starts to open. The pressure drop created by the pilot flow through the orifices (in the main poppet and the cover) is seen across the ends of the pilot piston, causing the piston to quickly move up and hold the pilot relief poppet off its seat. Full pilot flow at low pressure then creates sufficient pressure to fully lift the main poppet to open the mainstream flow path from A to B.

The valve remains in this condition until the reference pressure at port X drops to approximately 80% of the maximum, when the force of the pilot relief spring pushes the pilot piston back, allowing the pilot poppet to re-seat, bringing the system on-load again. Venting is controlled through port Z1. Design features providing smooth load/unload characteristics, with metering capability for partial unloading, together with stable operation are:

- Poppet is sliding spool type, with metering holes to give progressive opening.

- High gain pilot relief stage poppet.

- 20% differential pilot stage unloader piston.

Maximum Operating Pressure

- 350 bar (5000 psi)

Pressure Adjustment Range

- 3 to 125 bar (43 to 1800 psi)

- 5 to 250 bar (72 to 3600 psi)

- 8 to 350 bar (116 to 5000 psi)

Nominal Flow Rates

- At 5 bar (72 psi) pressure drop with valve unloaded.

Nominal sizes ISO 7368 (DIN 24342)

- 06 (NG16): 165 l/min (45 USgpm)

- 08 (NG25): 300 l/min (80 USgpm)

- 09 (NG32): 580 l/min (153 USgpm)

- 10 (NG40): 1000 l/min (264 USgpm)

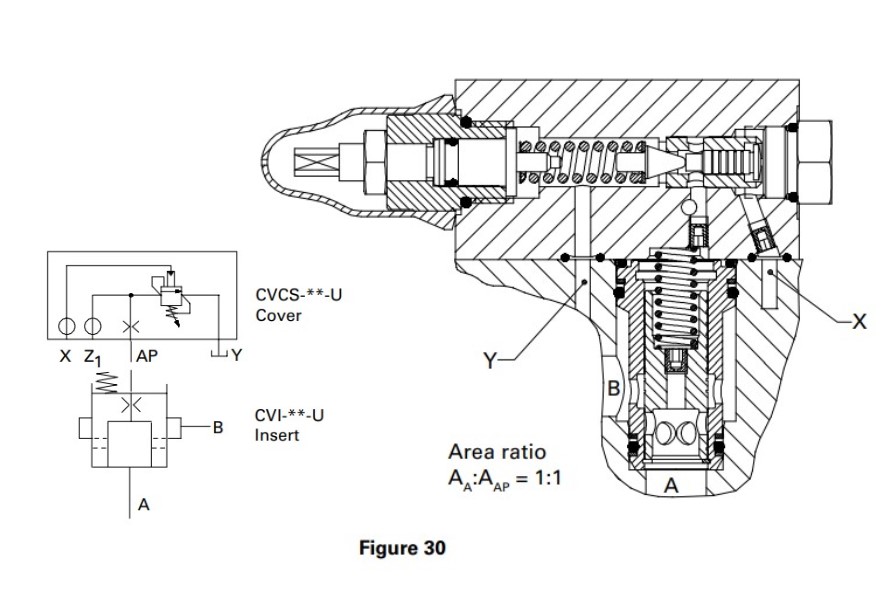

Pressure Unloading/Relief Functions

Pressure Relief and Unloading: Sizes 16 to 40

Pilot connection A to Z1 is needed to ensure the pressure relief function A to B. Pump flow at port A can be unloaded by application of pilot pressure to port X. This pressure must be equal to the pressure setting of the unloader pilot stage to initiate unloading; the system pressurizes again when this pressure drops by approx. 20% or more.

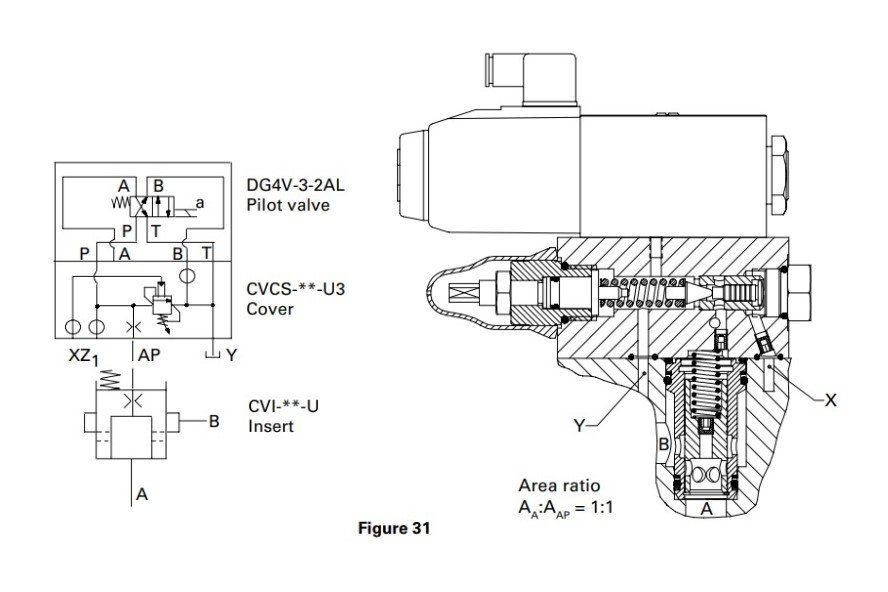

Pressure Relief and Unloading with Electrical Selection of Venting: Sizes 16 to 40

When it is required to unload the system independently of the system demands, this can be achieved by using the cover types U3 and selecting a suitable size 03 solenoid operated pilot valve. By using Danfoss Vickers model type DG4V-3-2AL for example, the system is unloaded when the solenoid is de-energized. When the solenoid is energized the unloader function operates (via pilot port X) as described above.